Gas pipeline installation works

During major works such as the installation of new gas pipelines, FOXTROT INTERNATIONAL's project and works teams coordinate the operational teams to master all the execution and construction sequences in order to guarantee the quality and reliability of the installations.

Commissioning of new installations

Before each integration of new equipment or new installations, the Project and Works teams carry out physical verification tests in order to leave reliable and immediately usable equipment for production. These tests and the manufacturer data are recorded and archived to keep their traces throughout the life of the equipment.

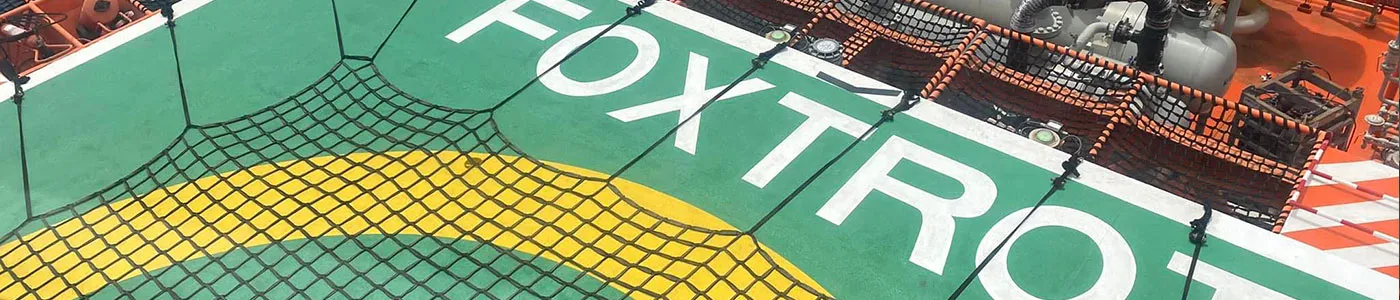

Riser installation works

The Project and Works teams are intended to work both at sea and on land, wherever FOXTROT INTERNATIONAL has oil installations. This requires strong motivation and the ability to adapt to different environments. Each subcontractor has in-depth knowledge of their profession and FOXTROT INTERNATIONAL agents combine their constraints for a winning synergy.

Installation of Slug Catcher Vridi Ouest

We sometimes have to deal with non-standard projects for which the means to be deployed are specific. It is then up to us to think about the different sequences of the work to find the means necessary for the proper completion of the work, such as using 2 cranes transported into the sand 100 km away from our bases, in a little-used area, in order to install a 40 T slug catcher at the exact location of its supports.

MARLIN Risers on FOXTROT

The integration of new projects on existing installations is part of our daily challenges. It is imperative to satisfy the production teams without disrupting their work. We carry out studies in advance for this, always keeping in mind that our work will be done in parallel with pressurized installations with all the risks that this can generate.

Pressure tapping

FOXTROT INTERNATIONAL calls on specialists to carry out special operations that require delicate know-how that we do not necessarily have in-house. This may involve, for example, welding on pressurized pipes, work requiring divers, specialized calculations in modeling. We always maintain control of these operations thanks to a permanent dialogue with these subcontractors and a certain knowledge of their professions that allows us to understand them and guide them on our installations.